Services

- 01 Weaving

- 02 Dyeing

- 03 Digital Printing

- 04 Rotary Printing

- 05 Embroide

01 Weaving

Weaving is the handiwork of enlivening textile or different materials with needle and string or yarn. Weaving may likewise consolidate different materials, for example, metal strips, pearls, dots, plumes, and sequins. Normal textiles with a tight weave, similar to cotton, material, silk and fleece, are the best textiles for machine and hand weaving. Machine weaving is a weaving procedure whereby a sewing machine or weaving machine is utilized to make designs on materials. It is utilized financially in item marking, corporate promoting, and uniform enhancement.

02 Dyeing

Coloring in materials is a procedure wherein shading is moved to a completed material or material (like filaments and yarns) to include perpetual and durable shading. It tends to be finished by hand or by machine. Colors can come as powders, precious stones, glues or fluid scatterings, and they break down totally in a watery arrangement like water. At the point when the material and the color come into contact, the material is totally soaked by the color and shaded. People have been coloring material for an incredibly, long time, and truth be told, researchers find early notice of coloring materials as far back as 2600 BC!

03 Digital Printing

Advanced imprinting on textile is another and imaginative procedure that includes printing a plan, an example or a picture straightforwardly from the PC onto the ideal media by method for a huge arrangement computerized printing machine. There are predominantly two effective computerized printing strategies: 1. Sublimation Digital Printing 2. Direct Digital Printing It normally alludes to proficient printing where little run occupations from work area distributing and other advanced sources are printed utilizing enormous configuration and additionally high-volume laser or inkjet printers. The inks utilized in advanced printing are figured explicitly for each kind of fiber (cotton, silk, polyester, nylon, and so forth). During the printing procedure, the textile is encouraged through the printer utilizing rollers and ink is applied to the surface as a large number of modest beads. Advanced textile printing gives noteworthy decreases in both water and power utilization when contrasted with conventional strategies for textile printing. Epson (sublimation) advanced printing machine has a computerized textile printing answer for essentially any textile type – from polyesters and mixes to common filaments, for example, silks, cotton, cloth, fleece, and rayon.

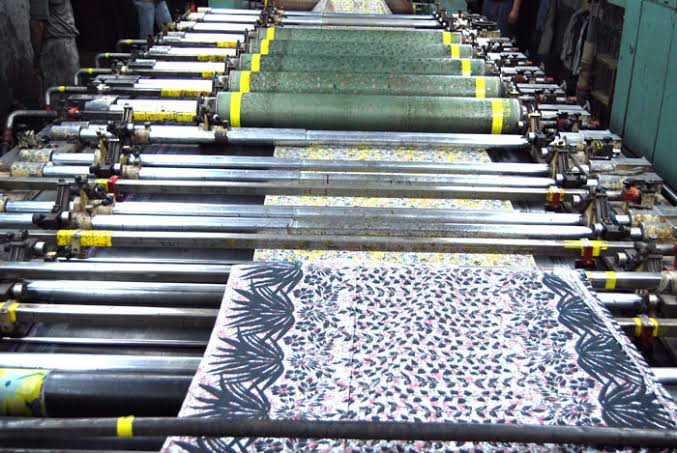

04 Rotary Printing

A revolving printing is a procedure where the pictures to be printed are bended around a chamber. It is apparently the most flexible of all printing procedures. It tends to be utilized to print on a wide assortment of substrates including materials. The benefit of turning printing over other print forms is that the press can print on substrates of any shape, thickness and size. A noteworthy quality of printing is that a more prominent thickness of the ink can be applied to the substrate than is conceivable with other printing methods. This takes into account some intriguing impacts that are impractical utilizing other printing strategies. In light of the effortlessness of the application procedure, a more extensive scope of inks and colors are accessible for use in screen-printing than for use in some other printing process. Usage of turning printing process has started to increment since creation rates have improved. This has been an aftereffect of the advancement of the robotized and rotating screen printing.

05 Embroidery

Embroidery is the handiwork of enlivening textile or different materials with needle and string or yarn. Weaving may likewise consolidate different materials, for example, metal strips, pearls, dots, plumes, and sequins. Normal textiles with a tight weave, similar to cotton, material, silk and fleece, are the best textiles for machine and hand weaving. Machine weaving is a weaving procedure whereby a sewing machine or weaving machine is utilized to make designs on materials. It is utilized financially in item marking, corporate promoting, and uniform enhancement.